Electromagnetic interference (EMI), also known as radio frequency interference (RFI), results when

an outside source causes noise or interference in an electrical path or circuit. Shielding is necessary

to prevent EMI from causing electronic devices to malfunction. Such malfunctions can range from

the innocuous — an odd noise on a car radio — to the serious — an accident related to failing

safety equipment.

As technology evolves, EMI shielding becomes increasingly important. The looming impact of the fifth generation of wireless technology (5G), the extending reach of the Internet of Things (IoT), and the growing electrification movement all have implications for EMI shielding. EMI shielding, as a key component of engineering design, should be considered at all levels of design from the PCB layout to the

enclosure. Engineers are faced with an array of shielding options to suit their needs at each design stage

and for each application, be it commercial, energy, defense, or others. This paper aims to give engineers a

look at what technological advances will challenge current approaches to EMI shielding and provides a

detailed overview of the materials currently on the market.

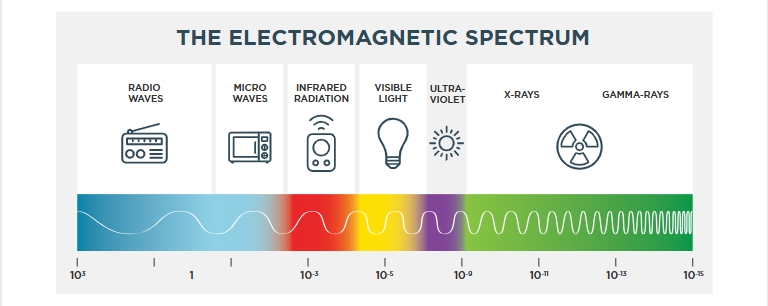

The Cisco Internet Business Solutions Group (IBSG) defined the IoT as the point in time when more

“things or objects” were connected to the internet than peopleii. By IBSG’s estimation, the IoT was born

around 2010 when the world’s population was 6.8 billion and the number of devices per person

connected to the internet was 1.84ii. Since then, the IoT has steadily crept into our world — both

personally and professionally. In our homes, it is becoming more common to control lighting and HVAC or to watch surveillance video footage of our front doors from our smart phones. Similarly, in our places of employment, the IoT allows for the connectivity of machines, vehicles, and systems. 5G has been considered by some to be a key enabler for IoT technology. With 5G comes the promise of faster data transmission as well as increased connectivity. The introduction of 5G to industry will create significant advances in the IoT. As a wireless network, industrial 5G will benefit from the elimination of cables within that environment, leading to greater flexibility and improved production layout. The very high speed of 5G is expected to eliminate lag and to improve productivity. Compared to frequencies for previous generations, frequencies in the 5G network have increased. In the United States, among the four major mobile carriers, frequencies in the second phase of 5G rollout range in the mid-band from 2.5GHz to 3.7GHziv. In Europe, regulators identified the 3.4-3.8GHz band as suitable for 5G, and it is the main frequency band for 5G. Higher frequencies in the millimeter wave bands 24GHz up to 86GHz are required for higher data rates. Even higher frequencies are expected as 5G advances. Compared to 4G, 5G with its high frequencies and high data rates will require many more base stations. Increases in data speed lead to commensurate increases in noise and heat. Greater connectivity supporting more wireless devices results in more signals and increased connector heat. All of these changes related to 5G place greater emphasis on appropriate EMI shielding, and as 5G evolves, engineers will need to meet the challenges of designing for faster data speeds, increased connectivity, and higher frequencies.

In addition to the challenges posed by 5G and the IoT, the growing trend in electrification is presenting

engineers with challenges from EMI. Government initiatives for alternatives to the internal combustion

engine are driving a boost in the electrification of vehicles — from personal vehicles to long-haul trucks,

delivery vans, farming equipment, and aircraftv.

By design, the electric vehicle represents a large amount of electrical content confined to a space. The

battery in an electric vehicle is one potential source of EMI. The all-electric vehicle has electromagnetic

fields between the two battery packs (traction and auxiliary), the DC/DC converter, and other system

components. Other types of electric vehicles — hybrid electric, plug-in hybrid electric, and fuel cell

electric — have an auxiliary battery, making them EMI susceptible as well. When considering EMI shielding

for electric vehicles, the engineer must also keep in mind the heat and flammability associated with the

battery. As with an increasing number of non-electric vehicles, electric vehicles may house navigation

systems and safety applications, such as advanced driver assistance systems, that also rely on

uninterrupted RF signals, representing additional areas for EMIv.

Beyond the electric vehicle itself are related EMI concerns. Electric charging stations (ECS) represent a

source of EMI due to the presence of AC and DC magnetic fields. The onboard electronics of the ECS

require shielding from EMI as well. Additionally, the electric vehicle is susceptible to external sources of

EMI ranging from common household items like garage door openers and cell phones to less frequently

encountered sources like solar storms and high voltage power linesv.

This article is posted at te.com

Please fill out the form to access the content