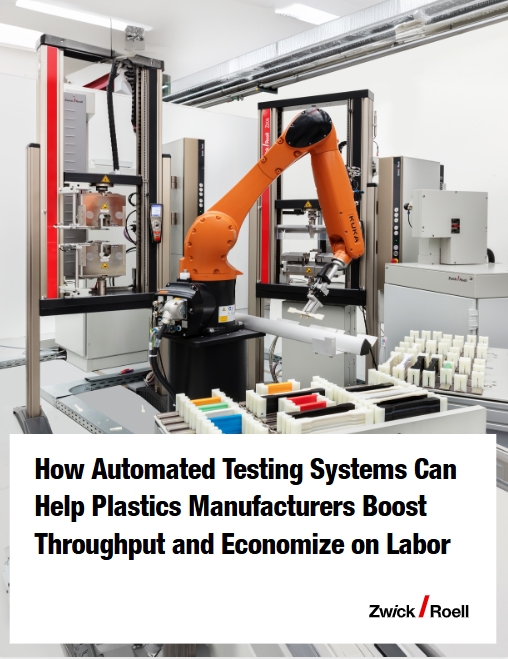

Boost Your Throughput and Reduce Labor Costs with Automated Testing Solutions for Plastics Manufacturers

In the fast-paced and ever-evolving plastics industry, manufacturers are under constant pressure to innovate and meet increasing demand while maintaining product quality. However, the ongoing labor shortage and the need for more precise, reliable testing solutions are creating operational challenges. Automated materials and component testing systems can offer the key to improving throughput, reducing labor costs, and ensuring more consistent results.

Why Automated Testing Matters in the Plastics Industry

Automated testing solutions are critical in addressing the unique demands of the plastics manufacturing process. Here’s how automation can help:

- Avoiding Human Error: Manual testing processes are prone to errors—whether from specimen handling, data entry, or typographical mistakes. By automating the testing procedure, manufacturers can eliminate the risk of human error, resulting in more accurate and reliable test data.

- Repeatable Results Across Multiple Sites: Consistency is crucial when testing materials and components across multiple locations or testing teams. Automated systems ensure repeatable results, maintaining uniformity in testing procedures and data capture, no matter the technician or the site.

- Maximizing Technician Efficiency: Skilled technicians are often tied up with routine tasks or waiting for results in manual processes. Automated systems free up technicians to focus on more valuable, decision-making activities, optimizing labor resources and reducing the time spent on mundane tasks.

- Cost Reduction: Even minor errors in testing—like incorrect measurements or missed keystrokes—can lead to costly product recalls or production delays. Automated testing minimizes these risks, reducing the chances of significant errors and delivering long-term cost savings.

The Key Benefits of Automated Testing for Plastics Manufacturers

Automated testing systems can provide numerous strategic advantages:

- Increased Speed and Throughput: Faster, more efficient testing allows manufacturers to keep up with the increasing demand for high-performance plastics without sacrificing quality or consistency.

- Reduced Labor Requirements: With less manual intervention needed, automation can help reduce reliance on labor, addressing the ongoing labor shortage while optimizing workforce efficiency.

- Improved Data Integrity and Reporting: Automated systems streamline the data reporting process, ensuring that test results are accurate, consistent, and easily accessible, particularly across multiple testing sites.

- Enhanced ROI: By improving testing precision, reducing labor costs, and preventing costly errors, automated solutions deliver substantial long-term ROI for plastics manufacturers.

How ZwickRoell’s Automated Testing Solutions Can Help

At ZwickRoell, we specialize in tailoring our testing solutions to meet the unique challenges of the plastics industry. Our testXpert software and testing machines provide automated, repeatable testing processes that improve quality assurance, data consistency, and operational efficiency.

- Automated Precision: ZwickRoell’s solutions deliver highly accurate measurements and eliminate human error through fully automated procedures.

- Seamless Multi-Site Integration: With testXpert, quality assurance departments can monitor real-time testing results from multiple sites and locations, ensuring standardization and consistency across the organization.

This article is posted at zwickroell.com

Please fill out the form to access the content